A COMPLETE SOLUTION FOR AUTOMATED WAREHOUSE MANAGEMENT

.Net

SQL Server

C#

HTML5

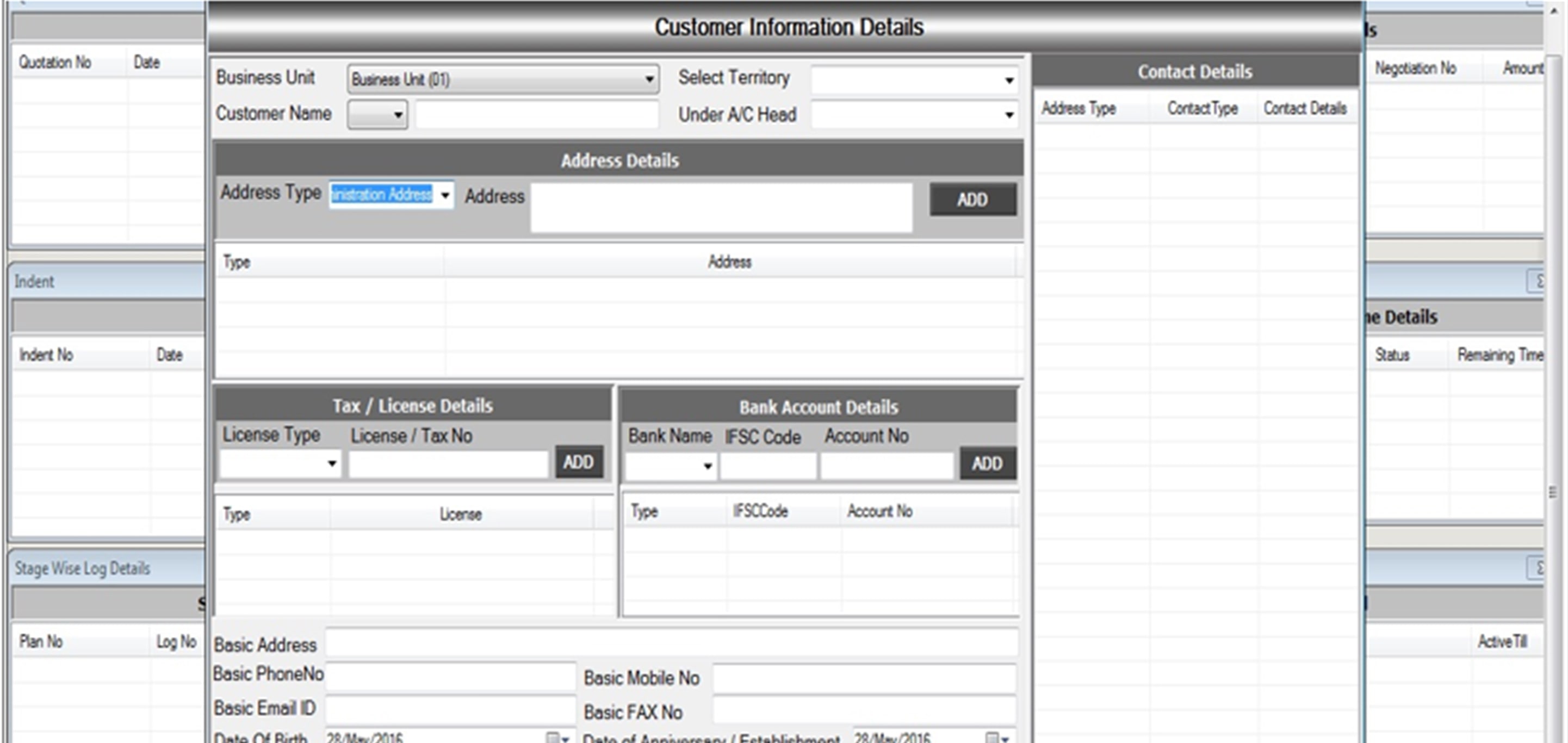

As technology is upgrading every industry wants to walk a step ahead and change the traditional ways of work. Automation is the new hype for several industry based businesses. Our esteemed Synthetic Moulder and Marco Polo also wanted to implement automation and ERP based technology to their Garments manufacturing business. Thus we started to custom build the Manufacturing ERP to cater to their requirements.

Our client came to us with a very simple request, they wanted to shift to an automated manufacturing ERP system and wanted to make a change towards the traditional way of work. We were able to deliver their requirement with ease as our main objective was to make this transition as smooth as possible. The UI was kept simple and stress was given in the functionality of the ERP

The results were really an eye opener for the client. Not only did this strategy of implementing the manufacturing ERP worked, it also improved a lot of things. Cost cutting was one of the main plus points of this ERP system as man power requirement decreased due to automation. Business revenue generation also skyrocketed, the finished products were reaching store shelves faster, due to automation and decreased manufacturing time.

Increase in Revenue

DECREASE CPA

INCREASE IN CONVERSIONS

RETURN ON AD SPEND

AVERAGE ORDERVALUE

LOADING TIME